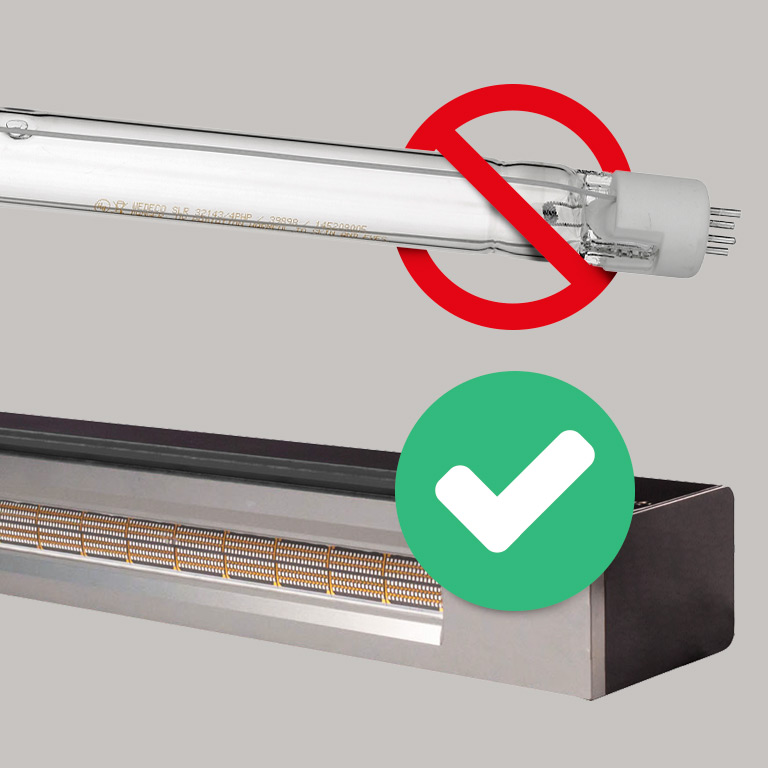

Replacing mercury lamps with eco-friendly LED technologies

Mercury is a toxic element and is slowly disappearing from a number of everyday products such as manometers, thermometers and dental amalgam. Mercury also serves a purpose in UV lamps. When electricity passes through mercury vapour in this kind of lamp, the result is a shortwave ultraviolet light that causes fluorescence. These lamps are used in the curing and pinning processes. Soon they will also disappear.

What does the EU directive say?

We are nearing the deadline announced by the EU for the elimination from drying ovens of UV lamps containing mercury. Procurement of these lamps is becoming more and more difficult as the upcoming ban affects import as well as manufacturing and usage.

What are the available solutions?

LED solutions we have developed in-house are able to replace UV lamps, extending service life by over 10 times, reducing operating costs and aligning to EU legislation.

Our LED solutions, developed in-house, are designed specifically for the curing or pinning of paints.

Why must UV lamps with mercury be replaced?

Inevitably, these lamps must be replaced, by law. Ovens using mercury-free lamps will be much safer and disposal of mercury-free lamps will be much easier. There are also significant advantages if you use an alternative lamp using LED technologies.

Overall energy consumption is between 50% and 70% lower than the same solution using a UV lamp containing mercury and the lifetime is estimated between 10 and 20 times longer, making maintenance needs minimal.

These lamps are activated and deactivated instantly without warm-up or cool-down times, which significantly reduces running costs.

The power of the lamps can be adjusted precisely, which guarantees ideal pinning performance.

Our LED solutions have been tested by major international paint manufacturers and their performance has been certified.

How is UV lamp replacement conducted?

Retrofitting an oven with our LED lamps is a straightforward process. A number of options can be implemented: from the replacement of the individual lamps to a LED module which can be fitted alongside the existing lamps, up to a complete oven replacement.

We have already set up our laboratory with different solutions, so that you can test your products and the pinning process.

The optimal solution will always be designed and evaluated based on your specific case, taking into account your production needs, application type, and performance targets, in order to ensure the best balance between efficiency, reliability, and investment.

Take a closer look at the different scenarios through a dedicated White Paper.

➡️ If you are using UV lamps, discover the solutions illustrated in this White Paper.